(708) 926-9567

Celebrating 10 Years of Excellence in Car Wash Chemicals and Car Wash Construction

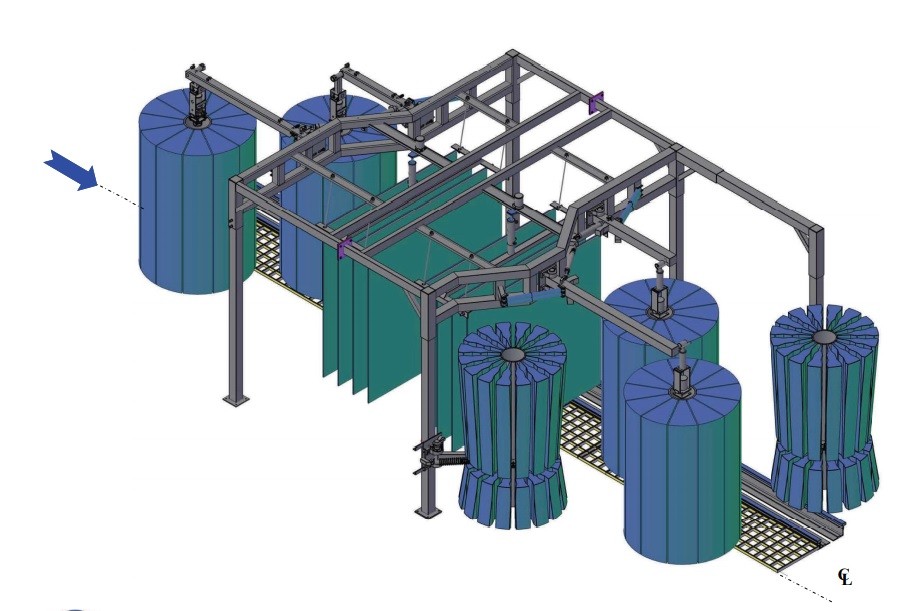

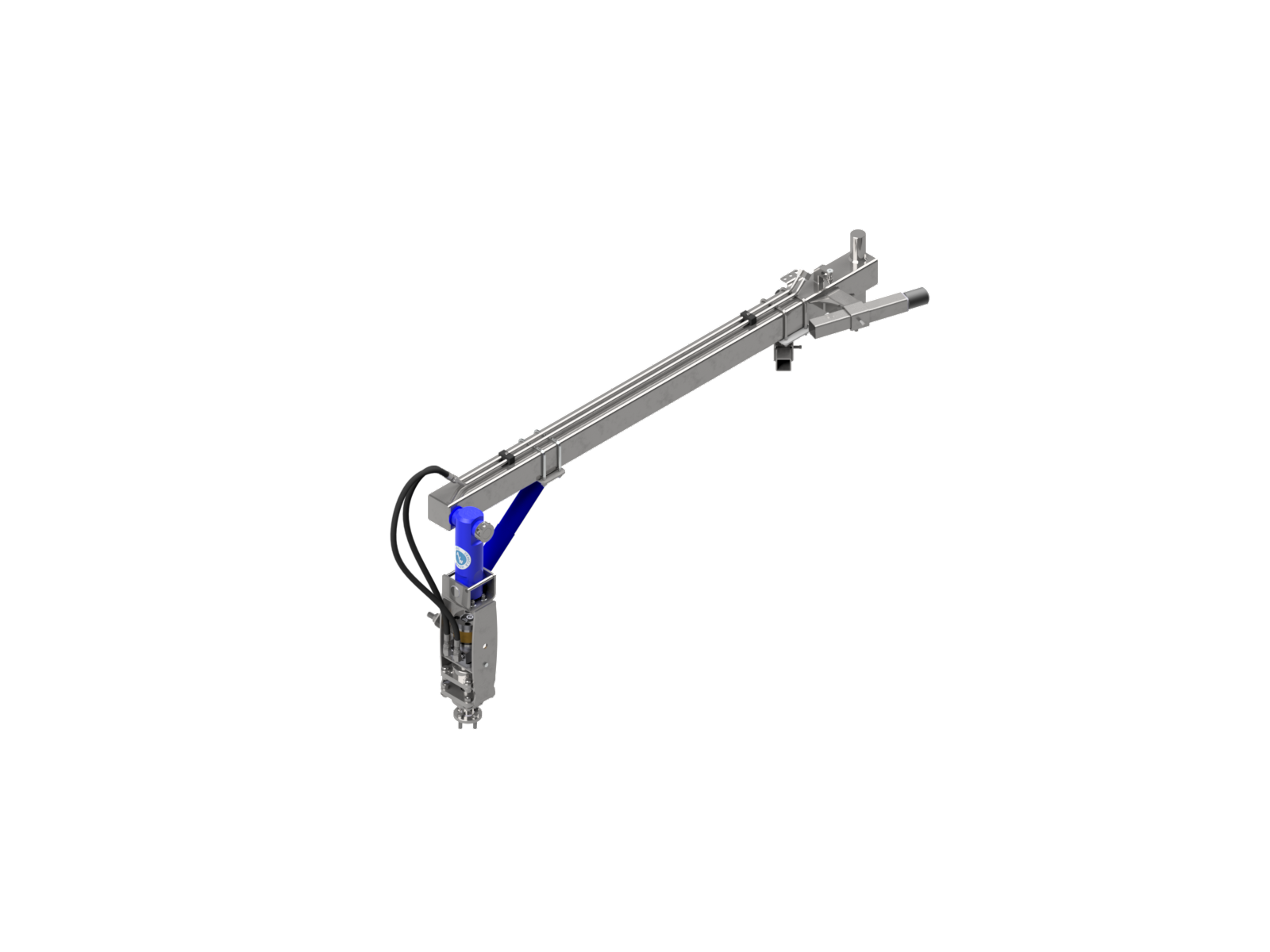

DUAL Z-WRAP w/DUAL MINI MITTER CONTOUR COMBO, Model 2WDM5CB0405

The Stainless Steel AVW - Z - Dual Wrap w/Dual Mini Mitter Combo and the best Mini Mitter combined in one unit ideal for space savings in tunnels and clean appearance desired in longer tunnels. Z-Wrap Around operate gravity. No complicated controls, because of the Design it can self adjust to most conveyor speed requirements. Simple design is constructed of heavy grade Stainless steel. Van High brush height is ideal for vans and sport utility vehicles because it cleans the sides with smooth even pressure.The AVW Contour is constructed of heavy grade Stainless steel designed to rotate reverse of the AVW Wrap Around and to provide constant pressure to the side of vehicles. Compact cleaning (12’) Retract kit is available

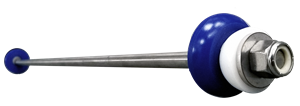

In order to get a higher application pressure at either driver side or passenger side of the machine, move the

bottom bearings towards the its center, or away from the center to achieve lower application pressure.

In order to get a higher application pressure at either driver side or passenger side of the machine, move the

bottom bearings towards the its center, or away from the center to achieve lower application pressure.

Brush climb up on back ends of the car

Possible Causes & Troubleshooting:

• The car is rolling ahead because of uneven floor and stopping with wrap on rear of car.

• Torque (Pressure) is set too high and brush will not stall as it climbs.

• Brush speed may be too fast. set at 60 RPM

• Brush may be set to travel more than 3/4 of backend of car / more swing after break- in period.

• Keep pivot point low as possible try not to mount over tire brushes or where high clearance is needed off the

floor.

• Car may be stopping or rolling because of a treadle on floor or pocket in floor

• If the friction is too high-apply more soap or lubrication.

• The faster the brush RPM, the more travel on the back of the vehicle-adjust RPM

Mirror is damaged or broken

Possible Causes & Troubleshooting:

• Lower portion of the brush is set to high coming into contact with mirrorstay below 33” from the top of the lower fuller section of the brush.

• Arm is restricted not to swing out far enough to clear the vehicle-adjust the

bumper so that brush can clear the vehicle.

• Too much tilt on the bearing causing excessive side pressure –adjust the tilt

on the bearing to reduce the pressure.

• Weak shocks absorbers-replace shock absorbers.

• Brush speed incorrect-set the speed.

Product Features:

- For Wrap Around: Displacement 12.05cu.in./rev., 18GPM, 60 RPM)

- Water: ½” NPT Outlet Equipment Center Line

- For Mini Mitter: 3.6GPM, 60RPM

- Water: 1/2’’NPT, 3GPM

- Hydraulic Motors

- For Contour Brushes: Displacement 5.0cu.in./rev. (= 1.3GPM at 60RPM, RPM is adjustable)

SKU Details

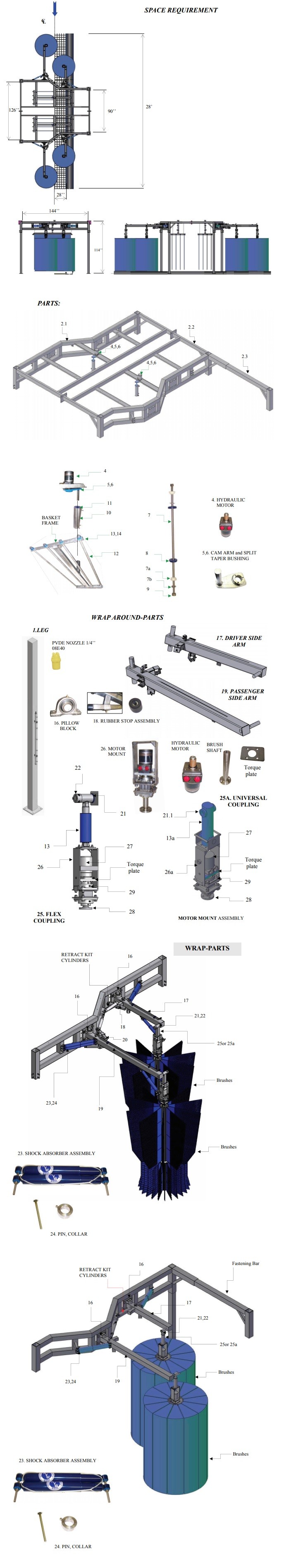

| Sku Images | Part# | Description | Diagram Part # | Quantity | |

|---|---|---|---|---|---|

| WC3A | Leg, w/Manifold, for Wrap Mitter Combo Leg, SS | 1 | 4 | ||

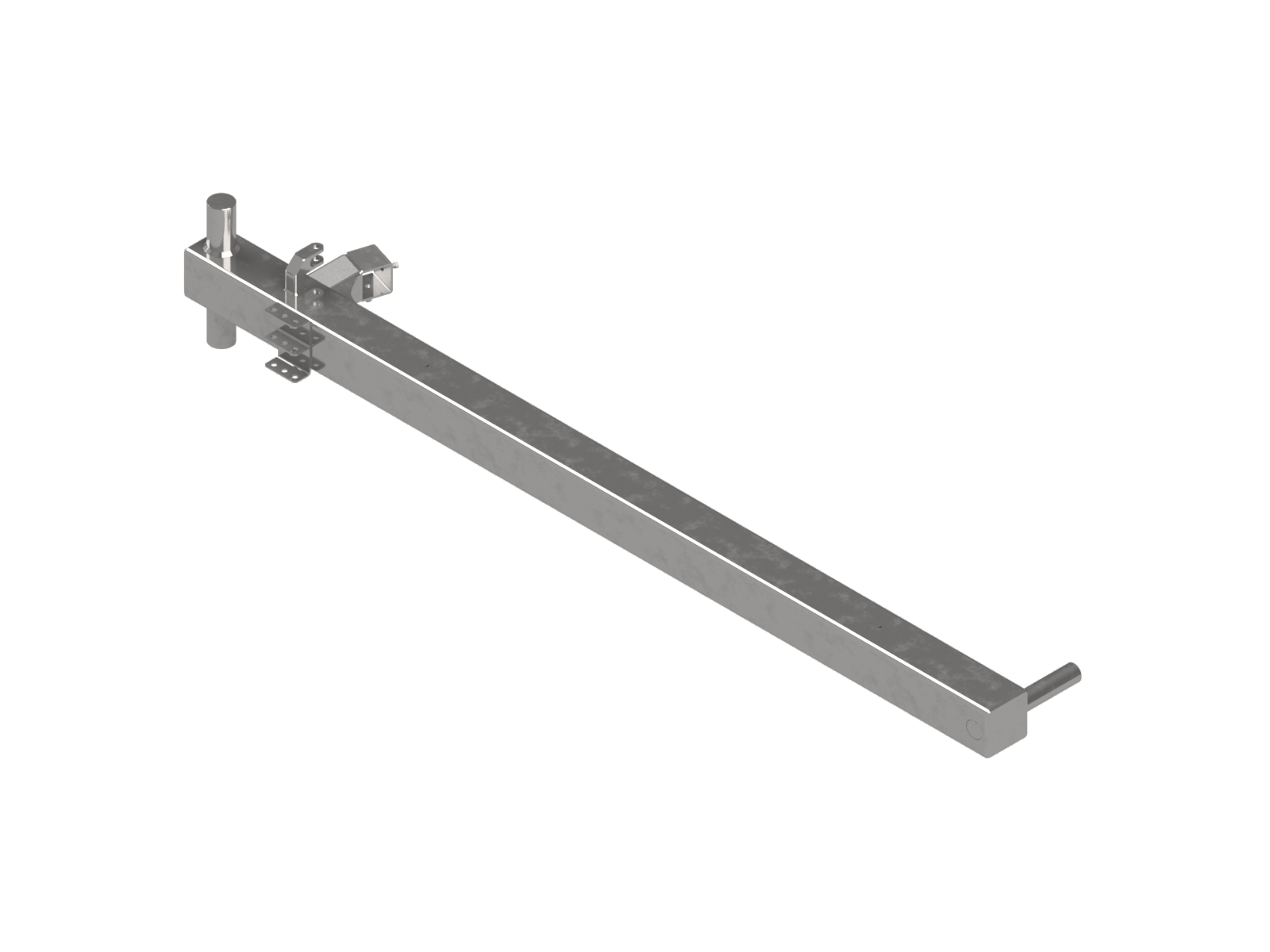

| 2WDM5AB | FRAME ASSEMBLY | 2 | 1 | ||

| 2WC3BA-1 | FRAME 1 | 2.1 | 1 | ||

| 2WC3B1C-2 | FRAME 2 | 2.2 | 1 | ||

| SQHS1213150 | Square head screw ½” - 13 x 1 ½” lg. (for sleeves) | - | 16 | ||

| HHCS3816200F | Hex Head Cap Screw 3/8’’-16x2’’LG | - | 8 | ||

| WACB1D | FASTENING BAR | 2.3 | 1 | ||

| SQHS1213150 | Square Head Screw ½” – 13 x 1½” LG. (for sleeves) | - | 4 | ||

| MC2BB-1104 | Basket Drive Assembly: | - | 2 | ||

| WA1KM | Hydraulic motor, displacement 11.9 [cu. in./rev.], | 44 | 22 | ||

| SAE070102-8-8 | Straight Fitting ½” NPTM x ½ ” JIC | - | 4 | ||

| MC2BBA-P1-0615 | Cam Arm (w/welded weld-on hub) | 5 | 2 | ||

| P1 1” | Split taper bushing P1 1” | 6 | 2 | ||

| HHCS3816075 | w/Hex Head Screw | -- | 88 | ||

| MC1C | BASKET SUPPORT ROD ASSEMBLY: | 8 | |||

| MC1C1 | Basket support Rod ½” x 27” lg. | 7 | 8 | ||

| MC1C2 | Basket support disk UHMW | 8 | 16 | ||

| MC1C3 | Basket support Halfball | 7a | 16 | ||

| FW12125 | Flat Washer 1/2”I.D.x1-1/4”O.D. | 7b7b | 1616 | ||

| NLN1213 | Nylon lock nut ½”-13 | 9 | 16 | ||

| MC2D | BASKET DRIVE ASSEMBLY: | - | 2 | ||

| MC2DA | Basket Frame 7’ | - | 2 | ||

| MC1DB | Sleeve assembly: | - | 2 | ||

| MC1DB1 | Sleeve | 10 | 2 | ||

| MC1DB2 | UHMW bushing 1” I.D. | 11 | 2 | ||

| SQHS3816075 | Square Head Screw 3/8”-16x ¾” lg. | -- | 66 | ||

| HN3816 | Hex nut 3/8”-16 | ---- | 6666 | ||

| MC2DC | Curtain Rod Assembly | - | 8 | ||

| MC2DCA | Curtain Rod 7’4”lg. | 12 | 8 | ||

| MC1DC2 | Plastic spacer 1” I.D.x2” O.D.x1/4” width | 13 | 16 | ||

| MC1DC1 | Plastic spacer 7/8” I.D.x1½” O.D.x3/16” width | 14 | 16 | ||

| PLHN3410 | Plastic Hex Nut 3/4”-10 | - | 32 | ||

| MC1E | CURTAIN (CLOTH) | 15 | 72 | ||

| WA1WB | PILLOW BLOCK 2” | 16 | 8 | ||

| - | ---- | 16161616 | |||

| HHCS1213225 | Hex Head Cap Screw ½”-13x2 ½”LG | - | 16 | ||

| SLW1/2 | Split Lock Washer | -- | 1616 | ||

| HN1213 | Hex nut 1/2”-13 | - | 16 | ||

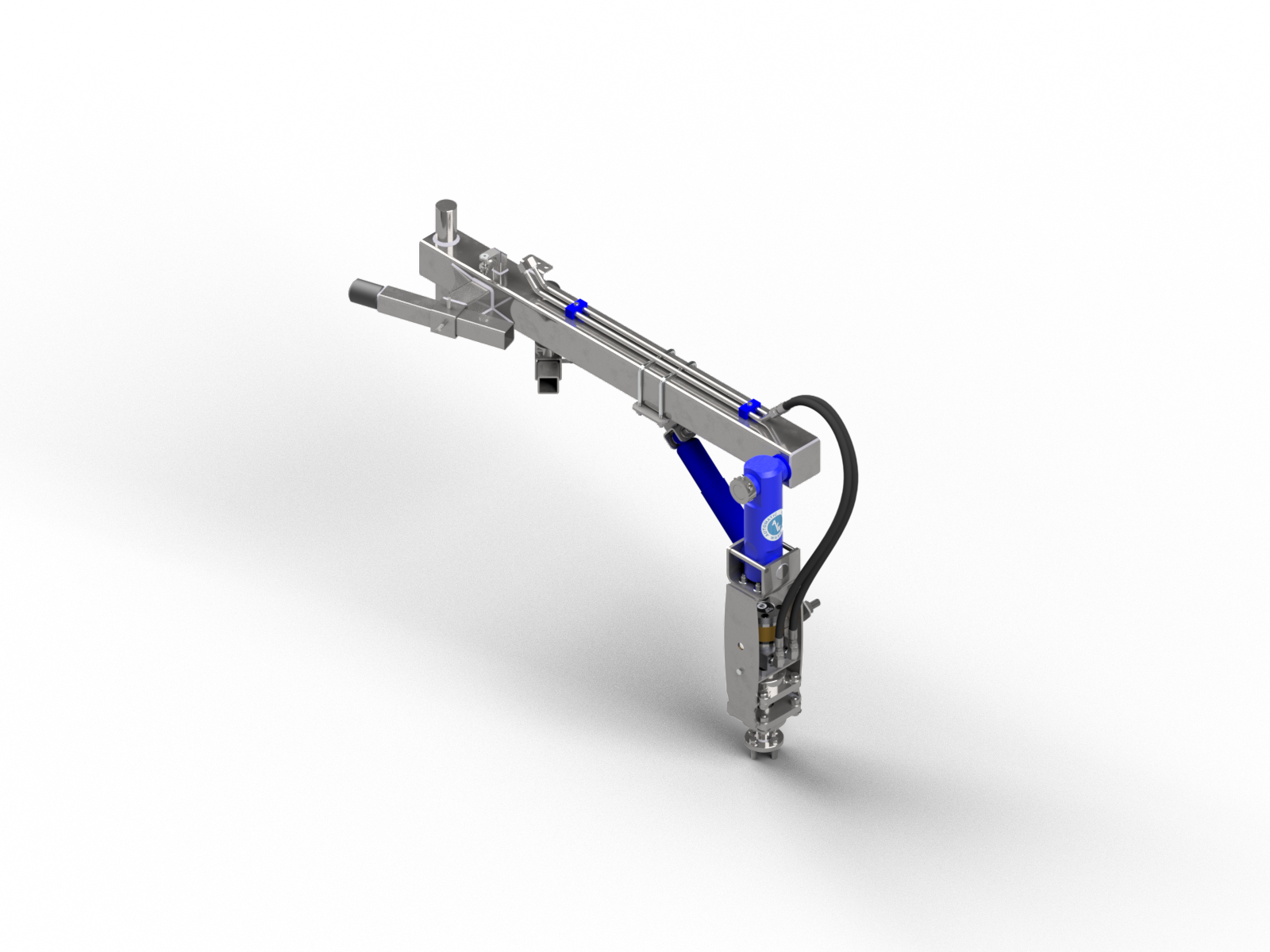

| WA1D | DRIVER SIDE ARM ASSEMBLY: | - | 2 | ||

| WA1DA | Driver Side Arm 48”lg. | 17 | 2 | ||

| WA1DB | Rubber Stop arm assembly: | 1818 | 44 | ||

| WA1DBA | Stop Arm | -- | 44 | ||

| WA1DBB | Rubber Bumper | - | 4 | ||

| - | Screw fastener set 3/8”, for collar | ----- | 44444 | ||

| HHCS3816125 | Hex Head Cap Screw 3/8” – 16 x 1 ¼” lg. | -- | 44 | ||

| FW38087 | Flat Washer 3/8” I.D. x 7/8” O.D | -- | 44 | ||

| SQHS3816075 | Square head screw 3/8”-16x ¾” lg. | - | 8 | ||

| WA1E | PASSENGER SIDE ARM ASSEMBLY: | 2 | |||

| WA1EA | Passenger Side Arm 76” LG | 19 | 2 | ||

| WA1DAD | BRACKET for RETRACT KIT (Welded to Arm) | - | 2 | ||

| WA1DBB | Rubber Bumper | - | 4 | ||

| FW38087 | Flat Washer 3/8”I.D.x7/8”O.D. | - | 4 | ||

| WA11 | PLASTIC SPACER | 21 | 4 | ||

| WA11-0112 | PLASTIC SPACER ( for UNIVERSAL COUPLING) | 21.1 | 4 | ||

| WA2J-2P | 2-PIECE COLLAR 1-1/2’’ | 22 | 4 | ||

| WA1FA | SHOCK ABSORBER ASSEMBLY: | 23 | 4 | ||

| WA1FAA | Shock Absorber Model MN32238 | - | 4 | ||

| WA1FA1 | UHMW Bushing 3/8” I.D. | - | 8 | ||

| WA1FB | PIN Æ3/8”x6”lg. | 24 | 8 | ||

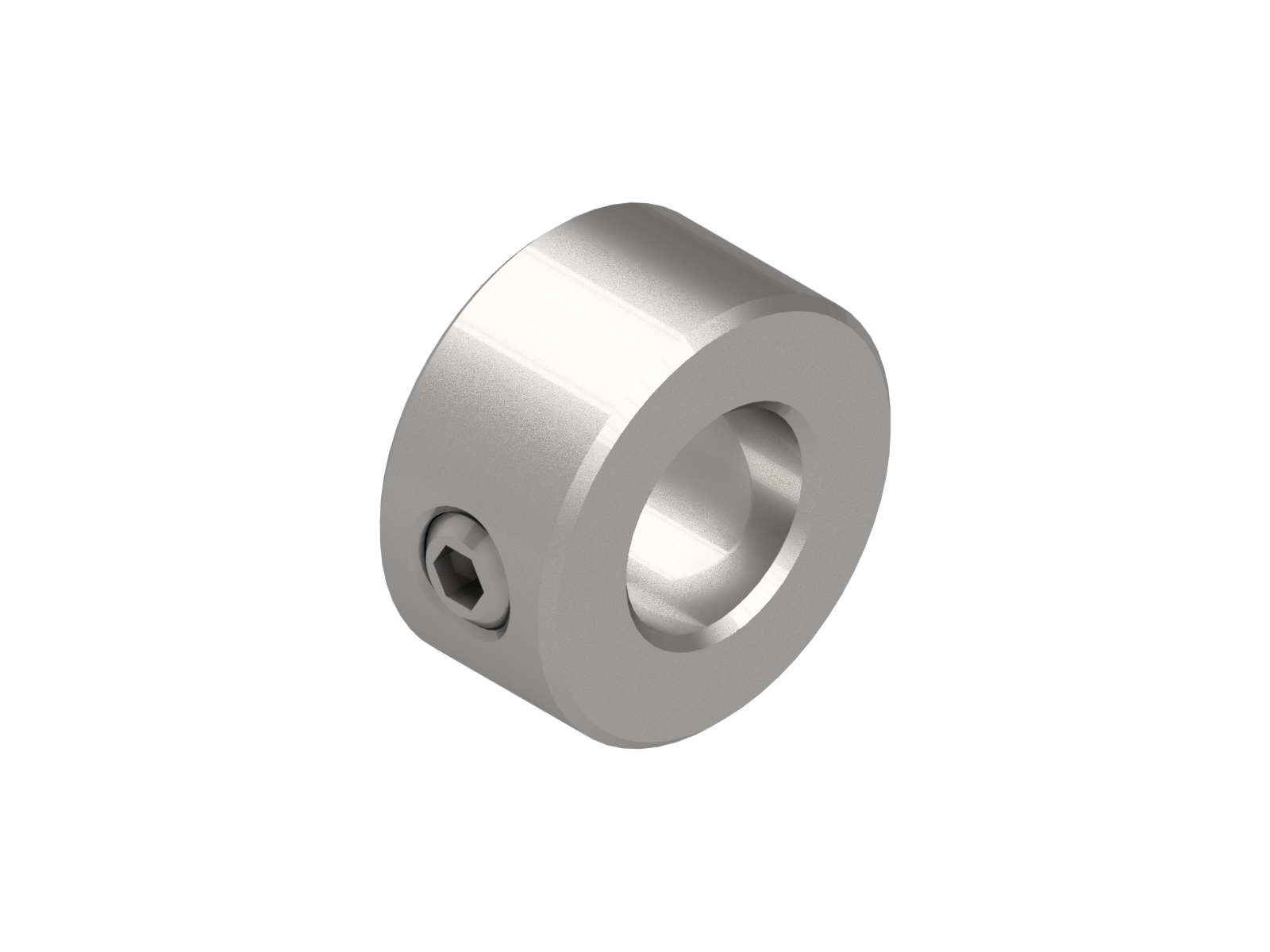

| WA1FC | COLLAR 3/8” | - | 8 | ||

| WA1H | FLEX COUPLING ASSEMBLY (optional) | 25 | 4 | ||

| WA1HA | Welded Flex Coupling | - | 4 | ||

| WA1HB | Wrap Cam ¾ ”I.D. | - | 4 | ||

| WA1H1 | UHMW Sleeve | - | 4 | ||

| WA1H2 | UHMW Bushing 1 ½” I.D. | - | 4 | ||

| WA2H-0112 | UNIVERSAL COUPLING ASSEMBLY | 25a | 4 | ||

| WA2HA-0112 | UHMW Flex Coupling | - | 4 | ||

| WA1H2 | UHMW Bushing 1½”I.D. | - | 4 | ||

| WA2HC | Mounting Channel | - | 4 | ||

| WA2HD | Shaft 1½” x 6¼”LG | - | 4 | ||

| WA1J | Collar 1 ½”I.D. x 2 ½’’ O.D. x 7/8” width | - | 8 | ||

| HHCS3816075 | Hex head cap screw 3/8”-16 x ¾ ”lg. (motor’s fastener) | -- | 1616 | ||

| WA5K | WRAP AROUND SHAFT ASSEMBLY | 26 | 4 | ||

| WA5KA | Motor Mount | - | 4 | ||

| NLN3816 | Nylon Lock Nut 3/8”-16 | - | 8 | ||

| SAE070202-8-8 | Fitting 90° elbow ½ ”NPTMx ½ ”JIC | - | 8 | ||

| WA1K1 | Torque Plate | - | 4 | ||

| WA5KB | Brush Shaft Æ1½”x10½”lg. | 28 | 4 | ||

| WA1KCB | 4-bolt Bearing 1½” UCF208-24E | 29 | 8 | ||

| HHCS1213175 | Hex Head Cap Screw ½”-13x1¾”lg. | - | 32 | ||

| FW12100 | Flat Washer ½ ”I.D.x1”O.D. | - | 32 | ||

| HN1213 | HEX NUT 1/2’’ | - | 32 | ||

| WA1M-5/10x72 | BRUSH ASSEMBLY (design: 5” core, 72”lg.) | 30 | 4 | ||

| WC3L | HYDRAULIC & WATER INSTALLATION | 31 | - | ||

| WA1LA | Side Water Manifold Assembly (on exit legs): | 4 | |||

| WA1LAA | Manifold | 4 | |||

| SAE140109P-8 | Hollow Hex Plug ½”NPTM | 4 | |||

| BRB1/2x1/2 | Barb 1/2”x ½” NPTM | -- | 4124 | ||

| NZ1/4 | Nozzle ¼” NPTM | - | 1616 | ||

| SAE140438-8-8 | Female Pipe Tee ½” NPTF | - | 4 | ||

| PPP3/4 | Pipe Clamp ¾”, for water hose and side water manifolds (w/screw fasteners ¼”) | 208 | |||

| MC1BC-S | Top Water Manifold Assembly | 4 | |||

| MC1BCA-S | Topwater manifold (tubing 1” O.D. x 34” LG. w/4 water outlets, 10” apart one from another | 4 | |||

| SAE140409P-8 | Hollow Hex Plug ½” NPTM | 4 | |||

| SAE070115-8 | Tube Support Sleeves ½” JIC | - | - | ||

| SAE070110-8 | Nuts ½” J | - | - | ||

| WA1LB | Hydraulic hose assembly: | - | - | ||

| SAE100R7-06x34 | Hydraulic Hose 3/8”I.D.x34”lg., thermoplastic, “Aeroquip” FC372-06 | - | 16 | ||

| FC5810-0806 | Crimp Fitting SAE 37° JIC swivel (female) “Aeroquip” | - | 8 | ||

| FC5807-0806 | Crimp fitting SAE 37° JIC male flare | - | 24 | ||

| DMP1/2 | Damping clamp ½”, for hydraulic tubes (w/screw fasteners ¼”-20) | - | 122 |